READ MORE

READ MORE

OF MANUFACTURING ANODISED ALUMINIUM

READ MORE

READ MORE

for manufacture of Anodised Aluminium Strips for Electromagnet Coils

READ MORE

READ MORE

Quality is never an accident it is always result of intelligent effort.

READ MORE

READ MORE

Manufacture and Supply of Anodized Aluminum Strips.

READ MORE

READ MORE

Asia's only manufacturer of Anodised Aluminium Strip for Electromagnets.

READ MORE

READ MORE

More kg of scrap lifted per KW of Power consumed.

ELEKTROFOL

KNOW-HOW

European manufacturers have been using Anodised Aluminium Strip for Lifting Magnets and Magnetic Separators for over 50 years.

Anodised Aluminium Strip is by far the best conductor material for Electromagnet Coils. It is far superior to conventional fibreglass or nomex covered Aluminium or Copper Wire or Strip. Elektromag has been importing Anodised Aluminium Strip from Germany since 2006 and winding the Magnet coils in India.

Elektromag’s anodising line has been commissioned in 2017 and since then we have anodised several hundred tones of Aluminium which have been used for production of numerous Lifting Magnets and Magnetic Separators

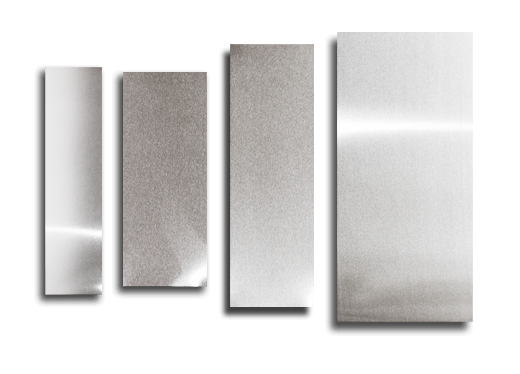

ANODISING PROCESS

The Anodising Process is an electrolytic process which results in the surface of the Aluminium Strip being converted to a layer of Aluminium Oxide which firmly adheres to the metal surface and forms a nearly homogenous bond with the Aluminium.

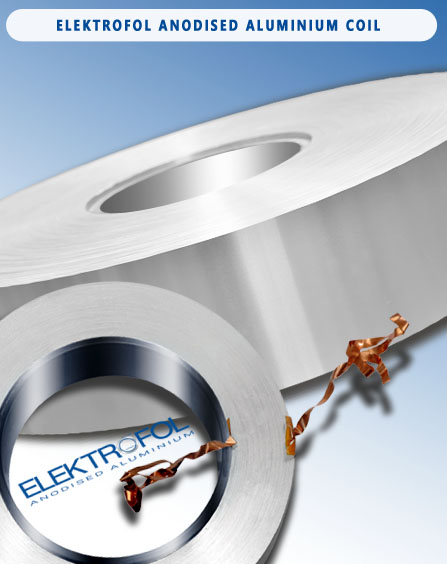

ANODISED ALUMINIUM COIL

Coils made of Anodised Aluminium Strip dissipate heat much faster since every single turn is itself part of the heat emitting exterior surface. In a conventional fibreglass or nomex covered and varnished wire coil, the dissipation of heat from the Coil centre is significantly obstructed.QUALITY ASSURANCE

Anodising Line is equipped with state-of-the-art equipment and trained manpower to ensure quality check at all stages, from incoming raw materials to finished product. Test Equipment includes all necessary Mechanical, Electrical and Chemical testing instrumentation.OUR PRODUCTS

Anodising Line

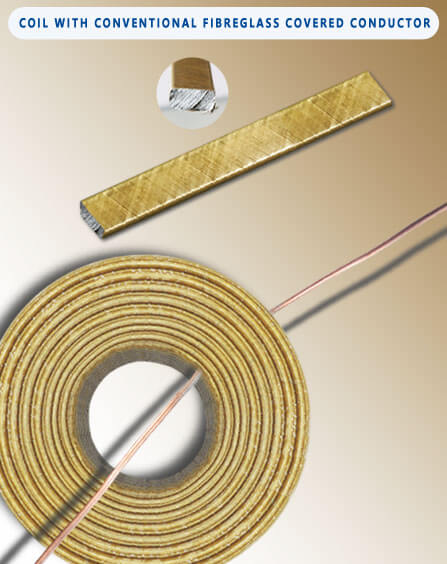

Lifting Magnets and Magnetic Separators manufactured in India have been traditionally wound with Fibreglass or Nomex covered Aluminium or Copper Wire or Strip

Anodised Aluminium Strip

European manufacturers have been using Anodised Aluminium Strip for Lifting Magnet and Magnetic Separators for over 50 years.

Anodised Aluminium Coil

Coils made of Anodised Aluminium Strip dissipate heat much faster since every single turn is itself part of the heat emitting exterior surface.

Elektrofol Anodised Aluminium

COMPARISON

Elektrofol Anodised Aluminium

COMPARISON

Anodising Process

The Anodising Process is an electrolytic process which results in the surface of the Aluminium Strip being converted to a layer of Aluminium Oxide which firmly adheres to the metal surface and forms a nearly homogeneous bond with the Aluminium.

QUALITY ASSURANCE

Coils made of Anodised Aluminium Strip dissipate heat much faster since every single turn is itself part of the heat emitting exterior surface.