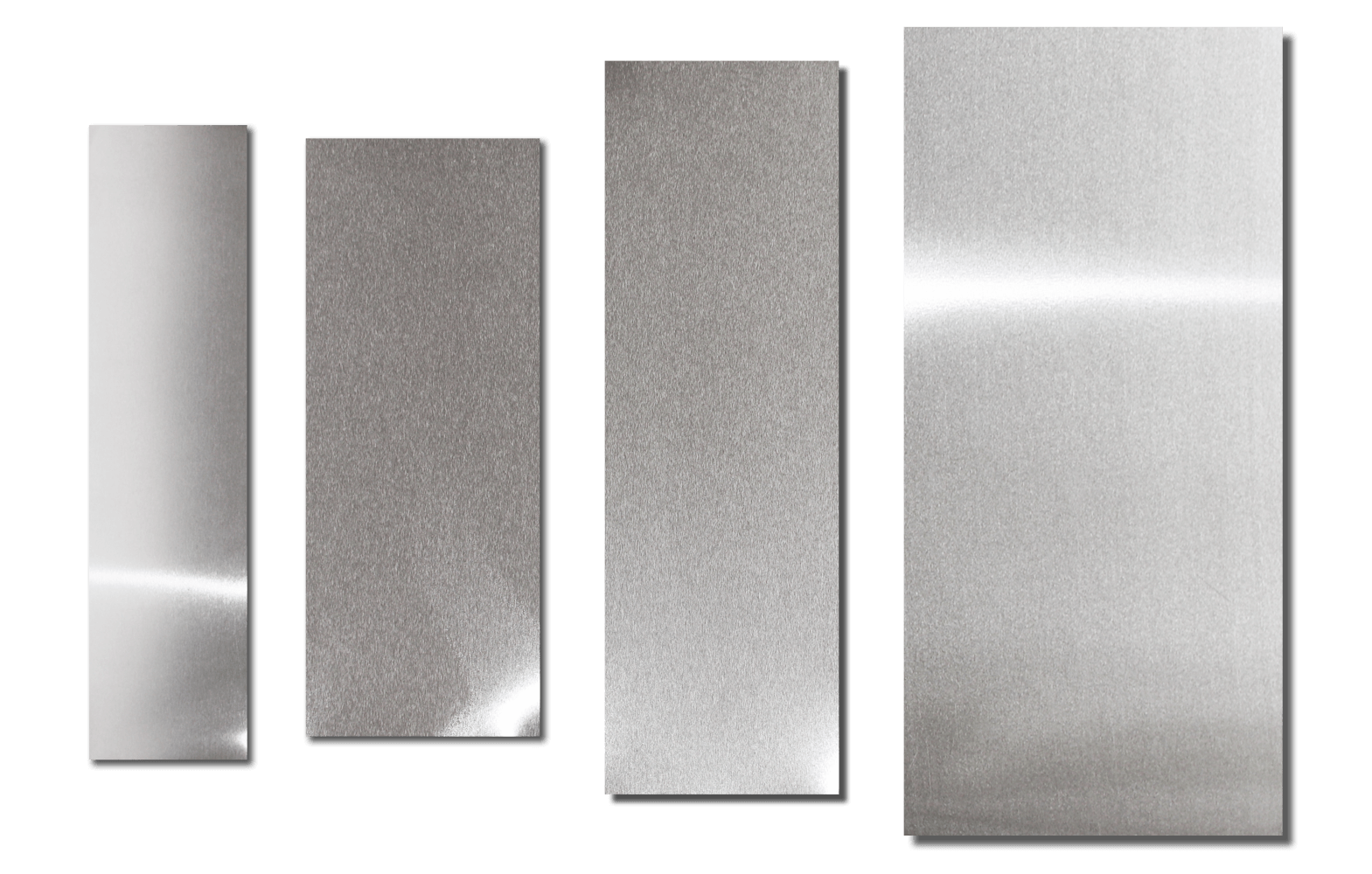

ANODISED ALUMINIUM STRIP

- Home

- /

- Anodised Aluminum Strip

Elektrofol

ANODISED ALUMINIUM STRIP

European manufacturers have been using Anodised Aluminum Strip for Lifting Magnet and Magnetic Separators for over 50 years.

Elektromag has been importing Anodised Aluminium Strip from Germany since 2006 and winding the Magnet Coils in India. Elektromag has already supplied a few hundred Electro Magnets with Anodised Aluminium Coils over the last 10 years. However, as the landed cost of imported Anodised Aluminium was very high, many customers, though aware of the advantages, were reluctant to pay the large price difference.

Now, in April 2017, Elektromag has commissioned its own Continuous Coil Anodising Line at Vapi in Gujarat, India, with technology acquired from Germany, to enable the Magnets to be more affordable.

The Anodising Process

The Anodising Process is an electrolytic process which results in the surface of the Aluminium Strip being converted to a layer of Aluminium Oxide which firmly adheres to the metal surface and forms a nearly homogeneous bond with the Aluminium. This oxide layer functions as an electrical insulator with insulating properties dependent on the oxide layer thickness. The oxide layer thickness is controlled during the Anodising process so as to meet the desired insulation level which would be adequate for the inter-turn voltage. For example, if the Inter-turn Voltage is 1V, then the insulating level would be in excess of 100V.

The Al2O3 aluminium oxide layer has high wear and abrasion resistance. It has a melting point of approximately 2000oC which exceeds the melting point of 658oC of the base Aluminium metal. Thus, effectively the oxide layer would have refractory properties and a Coil made from Anodised Aluminium Conductor could insulate till it melts.

The Anodising Process

Prior to Anodising, the Slit Aluminium Strip is subjected to a special edge preparation process. In this process, any remaining burr, after the slitting cycle, is removed and the edges are rounded to an appropriate radius.